Gain a Competitive Edge: Why Aftermarket Construction Parts Are Important for Success

Gain a Competitive Edge: Why Aftermarket Construction Parts Are Important for Success

Blog Article

Boost Performance With Aftermarket Parts: an Overview for Heavy Machinery Owners

Benefits of Aftermarket Parts

Proprietors of hefty equipment can appreciate numerous benefits by going with aftermarket parts over original devices maker (OEM) components. Among the key advantages is price financial savings. Aftermarket parts are typically extra economical than OEM parts, permitting equipment proprietors to decrease repair and maintenance prices without endangering on high quality. Furthermore, aftermarket components typically include guarantees, making sure that customers are protected in case of any kind of concerns or flaws.

An additional benefit of aftermarket parts is the bigger choice available in the market. Given that aftermarket makers specialize in creating particular components, equipment owners have accessibility to a wider range of choices to fit their needs. This selection can result in better performance and performance of the machinery. Moreover, aftermarket components are understood for their top quality and dependability, with several meeting or going beyond OEM requirements.

Lastly, selecting aftermarket components can additionally result in faster repair work and lowered downtime. With easier availability and fast delivery alternatives, equipment owners can get their tools up and running again quickly, decreasing disruptions to their operations.

Choosing the Right Aftermarket Parts

When thinking about aftermarket components for hefty equipment, it is vital to focus on compatibility and top quality to make certain optimum efficiency and long life of the tools. Selecting the best aftermarket parts can be an important choice for hefty machinery owners as it directly impacts the effectiveness and dependability of their devices.

Secondly, quality should never be compromised when choosing aftermarket components (aftermarket construction parts). Selecting high-quality components makes certain durability, reliability, and overall efficiency of the equipment. It is a good idea to source aftermarket parts from reliable manufacturers or vendors recognized for their high quality standards

Additionally, taking into consideration variables such as guarantees, customer testimonials, and compatibility with existing systems can better assist in making the ideal choice. By prioritizing compatibility and top quality when choosing aftermarket parts, hefty machinery owners can boost the performance and durability of their tools.

Setup and Maintenance Tips

For effective operation and longevity of heavy equipment, correct setup and regular upkeep are extremely important. When setting up aftermarket components, ensure that you meticulously comply with the supplier's instructions to ensure ideal performance. It is vital to make use of the appropriate devices and strategies to avoid any kind of damage throughout the setup procedure. Routine maintenance is vital to keep your machinery running efficiently. Establish an upkeep routine that consists of jobs such as inspecting liquid levels, inspecting for deterioration, and cleansing elements (aftermarket construction parts). Immediately resolve any problems that emerge to stop additional damage and expensive repair work. In addition, take into consideration buying training for your maintenance staff to ensure they have the read this required abilities to recognize and address prospective troubles. By focusing on installment and upkeep treatments, you can optimize the efficiency and life expectancy of your hefty machinery, eventually saving money and time in the lengthy run.

Cost-Effectiveness of Aftermarket Components

Proper installation and regular maintenance are foundational aspects for heavy machinery owners intending to assess the cost-effectiveness of aftermarket parts for their equipment. While original equipment manufacturer (OEM) parts are known for their quality, aftermarket components use an even more affordable option without jeopardizing performance. By thoroughly reviewing the high quality and compatibility of aftermarket parts with their machinery, owners can strike a balance in between cost-effectiveness and efficiency, eventually making best use of the performance and longevity of their heavy tools.

Maximizing Performance With Aftermarket Upgrades

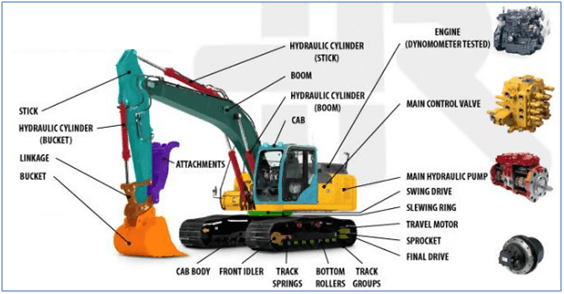

To boost operational performance and performance, hefty machinery owners can efficiently take full advantage of effectiveness through critical use of aftermarket upgrades. Aftermarket upgrades use the opportunity to customize heavy equipment to particular operational demands, leading to boosted capability and output. Updating elements such as engines, transmissions, hydraulic systems, and tracks can considerably improve the overall performance of the machinery.

On a regular basis assessing the efficiency of heavy equipment and recognizing areas where aftermarket upgrades can be useful is essential for optimizing efficiency. By investing in high quality aftermarket components and upgrades, equipment owners can achieve greater levels of performance, eventually causing set you back savings and improved operational outcomes.

Final Thought

In verdict, aftermarket components offer various benefits for heavy equipment proprietors, consisting of cost-effectiveness, raised efficiency, and customization options. By selecting the right aftermarket parts, complying with appropriate setup and upkeep treatments, and making best use of upgrades, hefty equipment proprietors can enhance their equipment's performance and longevity. Purchasing aftermarket parts can ultimately cause improved productivity and reduced downtime, making it a worthwhile consideration for proprietors aiming to maximize their equipment procedures.

Proprietors of hefty machinery can delight in various benefits by opting for aftermarket parts visit here over original equipment supplier (OEM) components. Aftermarket components are usually much more cost effective than OEM components, enabling machinery owners to decrease upkeep and fixing expenses without jeopardizing on quality. By meticulously reviewing the high quality and compatibility of aftermarket parts with their equipment, owners can strike an equilibrium in between cost-effectiveness and efficiency, eventually making the most of the effectiveness and longevity of their hefty devices.

In conclusion, aftermarket components supply various benefits for hefty machinery proprietors, including cost-effectiveness, raised effectiveness, and customization choices. By picking the best aftermarket components, complying with proper installation and maintenance procedures, and making best use of upgrades, heavy equipment owners can increase their tools's efficiency and durability.

Report this page